Services you may be looking

Reason For Choosing Us

Understanding Requirement

We are experienced engineers who prioritize understanding project and client requirements. This essential aspect of engineering ensures successful outcomes. We pay close attention to each project, identifying every detail and specification needed. This strengthens our ability to provide tailored solutions to meet each client’s specific needs. We prioritize your project and work tirelessly to exceed your expectations.

Meticulous Planning

Our company is committed to exceptional customer service with on-time deliveries to meet client expectations. The coordination of deliveries is attributed to our scheduling engineers who work closely with clients to personalize their experience. Experience the difference today with our reliable, efficient and customer-focused delivery service.

Execution and Quality

Our company has an excellent team who are highly skilled and experienced. We are dedicated to managing projects from the start with the utmost attention and attention to detail. We use high-quality resources to create outcomes that exceed our clients’ expectations. Our goal is to provide clients with high-end deliverables that will make them happy and satisfied. You can trust our team to provide you with the best project experience from start to finish.

Deliver Beyond Expectation

At our organization, we hold a strong emphasis on the importance of successful project delivery, and we achieve this by maintaining exceptionally high standards of quality and ensuring the timely completion of each and every project. We are dedicated to ensuring that every customer we work with receives the highest level of service and satisfaction in all that we do, and that their expectations are always exceeded.

What we do..!

Structural Design

Gravity Steel Structures are expert in the field of structural steel design and analysis. We deliver various engineering designs which includes structural design, design analysis, load analysis.

We have provided the design services for various projects like, Industrial, Commercial Residential projects which includes High rise buildings, Commercial complex, Sky Scrapers, Manufacturing Plants, Factories, Sheds, Buildings & Apartments, Platforms, Staircases, Railings, Pipe racks, Ladders, Tanks, Etc. Adhering to our ethical and transparent work culture norms, all design and analysis are performed to meet AISC, CISC, IS and other codes with latest editions and applicable material-specific design codes and standards.

Our Connection Design Services includes

- Structural Steel Design and Analysis

- Design Sketches

- Peer review services

- Value engineering services

- Alternate material design checks.

- Structural Steel Design and Analysis

- Design Sketches & Connection detail drawings.

- Peer review services

- Value engineering services

- Alternate material design checks.

Structural design is the process of creating a safe and functional structure under any load that it may experience. Generally, there are four steps: (1)modelling, (2) load analysis, (3) structural analysis, and (4) design.

The first step is to model the structure’s skeleton, such as its foundations, columns, beams, frames, trusses, and other elements. It depends on the designer on how to model it; however, it’s essential that it can anticipate loads since it would be the basis for the whole process.

Furthermore, modelling involves determining the structure’s material whether it would be “structural steel”, “reinforced or prestressed concrete”, “timber”, or any material. Also, it involves assuming dimensions for each element which is the basis for self-weight computation for the next part.

The first step is to model the structure’s skeleton, such as its foundations, columns, beams, frames, trusses, and other elements. It depends on the designer on how to model it; however, it’s essential that it can anticipate loads since it would be the basis for the whole process.

Furthermore, modelling involves determining the structure’s material whether it would be “structural steel”, “reinforced or prestressed concrete”, “timber”, or any material. Also, it involves assuming dimensions for each element which is the basis for self-weight computation for the next part.

one must identify all of the possible loads that the structure may experience during its lifetime. Moreover, these loads are actions that threaten the structure to serve its purpose. Usually, the values of these loads can be identified using structural codes and references.

different loads act simultaneously with the structure; hence, to accommodate this instance, load analysis also involves creating load combinations depending on the standards used. For instance, a simultaneous action between dead load (weight of the structure) and live load (use of the building by people) can be a load combination

Structural design is, perhaps, the most important step in the process. It involves dimensioning the different parts of the building based on the results of the analysis. Also, it is concerned with choosing the right orientation, section, and other details that are relevant to the structure.

Structural Design

For proper design, it would depend on the philosophy used (strength-based or performance-based). Ideally, the designer must follow the requirements of the code used. Eventually, at the end of this process are drawings of the different elements that can be used to build the structure.

After identifying such loads comes structural analysis. The goal here is to investigate how does your model behave with the different load combinations made.

There are different methods to analyse a structure and would depend on a lot of factors. For example, one common method is the use of classical methods such as the “moment distribution method” and the “slope-deflection method”. This method is easy for simple structures, but for more complicated ones, another option to use is the matrix method (stiffness method).

Structural Design Analysis

A full analysis of a structure usually entails identifying the internal effects of different load combinations (normal, shear, moment, and torsion stresses), and the deformation/deflection of the structure. As a result, the observed effects would be the basis for designing the individual elements of the structure.

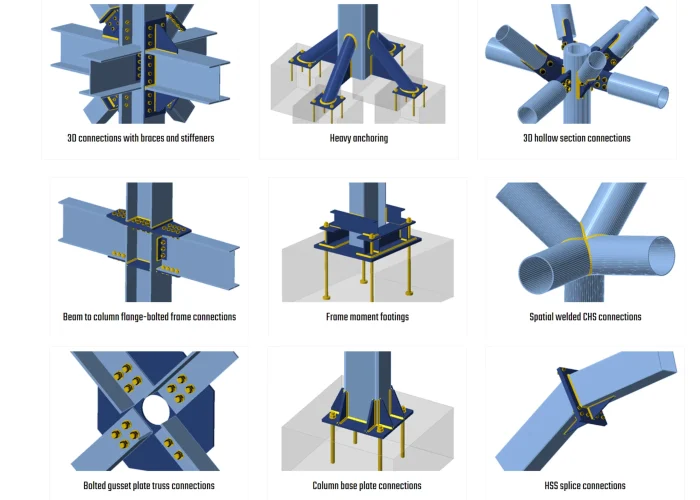

Connection Design

Steel structures require a lot of careful planning and design to ensure they are safe, stable, and meet the necessary standards. At our company, we take pride in offering a complete range of connection designs for steel structures, designed to comply with various international standards, including BIS, AISC, BS, CISC, and more. Our team of highly skilled and experienced engineers specializes in structural steel connection design, utilizing advanced software tailored to meet each client's specific needs.

We understand that each project is unique, and we take the time to carefully analyze all the factors involved in order to formulate a comprehensive and accurate design plan that ensures the sustainability of the structure. Our engineers are well-versed in all the global standards, including LRFD by AISC, IS, BSi, ASi, and others, and we use a range of software tools, including Idea Staica, Limcon, spreadsheets, and hand calculations, to provide the most precise and reliable data possible. With our expert connection designs, you can be confident that your steel structure will be built to the highest standards of safety and sustainability, ensuring its long-term durability and performance.

Our Connection Design Services includes

- Connection Design and Analysis

- Connection Marking Plan drawings.

- Shear Connection Design

- Moment Connection Design

- Axial Connection Design

- Connection Design and Analysis

- Connection Marking Plan drawings.

- Shear Connection Design

- Moment Connection Design

- Axial Connection Design

We accept analytical, premonitory and detailed design projects and are strengthened by our engineers and technical team with vast experience in the field.

In order to complete the necessary structural design analysis our team of design engineers with coordinate with the client / owner to understand the requirement.

We adapt their structural analysis approach to conform to your requirements and structural standards. This will allow the input of information in the form of various reporting and standards.

We also work with client to develop design standards and a communication plan that will ensure consistent, repeatable and high quality performance.

The end result will be complete structural detail drawings, layout of plans, elevation, section and legends in 2D or 3D formats as per requirements.

The result is a seamless flow of information in the form of desired format and spreadsheets will be provided.

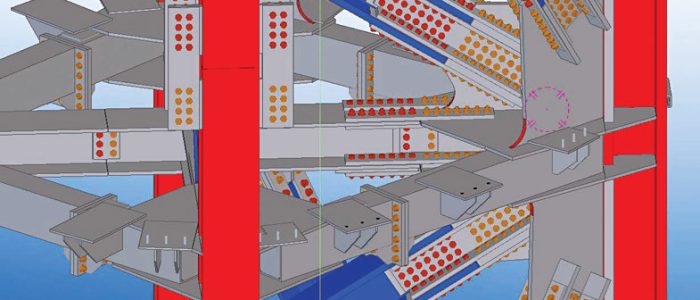

Structural Steel Detailing

We are Providing the comprehensive solutions for structural steel detailing services. We work round the clock to ensure seamless communication with all our clients. More importantly, we have teams that visit our clients on a regular basis to address their project needs and update their skills.

we understand and respect your delivery time lines. With our increased speed and capacity, you can optimize on your core strength of procuring more business. Strengthen your relationship with your client by bringing optimization value to them; mitigate the negative impact of revisions and reduce shop turnaround times.

Our Steek Detailing Services includes

- 3D Modelling by Tekla Structures / SDS2

- Connections of Members

- Anchor Bolt Plans

- Erection / General Arrangement Drawings

- Fabrication / Shop Drawings

- Single Part / Gather Drawings

- 3D Modelling by Tekla Structures / SDS2

- Connections of Members

- Anchor Bolt Plans

- Erection / General Arrangement Drawings

- Fabrication / Shop Drawings

- Single Part / Gather Drawings

Gravitye Steel Structures is a leading provider of complete solutions for 3D modeling services. Our expertise lies in Tekla & SDS/2 software for industrial, commercial, residential infrastructure and manufacturing as well as other structural steel projects. Our team of highly skilled engineers has vast and rich experience in working on international projects. We are committed to visualizing the complexity of projects, addressing specific real-time fabrication issues, and adapting to detailing shop and GA drawings to enhance the efficacy of project managers and fabricators, to ensure successful completion of the projects within the given schedule. All our team members are trained in AISC/ NISD, IS, CISC and other standards.

We have executed tons of structural and miscellaneous steel detailing jobs in a variety of buildings and structures. Our team of experts stands out in addressing the potential needs of fabricators, owners, architects and general contractors by drawing on our extensive experience and innovation. Our unique BIM based 3-D modeling approach facilitates the checking of any clashes or interferences during the detailing stage. This saves a considerable amount of time and resources in modifications at the site. We also provide bolted steel structures with accurately designed bolted connections. This allows for fabrication of structures in workshops instead of site fabrication, resulting in faster erection and better aesthetics of structures.

Fabrication Drawings will have 2 categories, Assembly Drawings & Singe Part Drawings. Single-part drawings are crucial for the manufacturing and fabrication processes. They provide comprehensive information about the specific dimensions, materials, and tolerances for each component. Manufacturers and fabricators use these drawings to produce the parts accurately and according to project specifications Single part drawings will have the cutting & welding information of the member and all the single parts will be assembled based on the assembly drawings.

Shop drawings (also known as fabrication drawings) are detailed plans that translate design intent. They provide fabricators with the information necessary to manufacture, fabricate, assemble and install all the components of a structure. This includes materials and dimensions required, as well as explanations for assembly, installation and erection. In general, engineers, steel detailers, steel modelers and fabricators are responsible for creating shop drawings. They generally include the following information:

- Information required for fabrication, such as dimensions and special instructions including connection details

- Applicable fabrication standards

- Installation and erection information

- Dimensions that require on-site verification

- Comparisons to the construction documents to enable approval by the architect or engineerNotes on changes from the construction documents to enable approval by the architect or engineer.

Why Shop Drawings are Important

Precise, accurate structural steel fabrication drawings are essential and can help:

- Ensure clear communication between the architect or designer, the client, and the fabricator.

- Ensure that the fabrication process flows seamlessly, as there is no need to halt fabrication to confirm missing details or dimensions. In this way, shop drawings help to expedite the timeline of construction.

- Provide the fabricator with sufficient detail to ensure that steel elements are structurally sound and adhere to all necessary safety, quality and project standards.

- Reduce, or even eliminate, fabrication rework by resolving issues and clashes early on. As such, unnecessary expenditure on additional labor and materials are avoided.

Erection Drawings also known as General Arrangement Drawings, include all drawings, diagrams, design calculations, procedure manuals and other data required to depict in detail the proposed assembly and methods of installation of components into the project work. The work of construction is the expertise of the Contractor, who should be allowed some latitude in the use of construction means, methods, techniques, sequences and procedures as are compatible with and will result in the project being completed in accordance with the requirements of the Contract Plans and

Specifications. Shop Drawings for items such as steel girders, non-standard precast/prestressed beams, miscellaneous steel, etc., usually include plan views and/or elevation views denoting the correct placement of a component in the structure. Additional

Erection Drawings are required for major structures for items such as special precasting, handling and erection equipment, or the erection of concrete segmental bridges. The Engineer of Record must ensure that the Contract Plans and Special Provisions for the

project clearly define all requirements for submittal of Erection Drawings.

- Floor plans and sections of the steel structure in coordinate axesto show, how the assemblies of the steel structures are arranged towards each other and interconnected in space

- Local sections, view, structural steel connectionand other images that give a complete picture of how the assemblies (beams, columns, braces, etc.) are connected

- Markings (names) of assembliesspecifying the profile (section) of the main part of the assembly of steel frame elements

- Connection type of steel frame elementsconnection type of assemblies (mounting bolts, strength grade, standard and sizes of bolts, nuts and washers, or applying site welding, showing the type of the weld dimensions)

- Dimensionssnapping of steel frame elements to coordinate axes, distances between steel frame elements, snapping of connection elements, dimensions of openings etc.

- Technical instructions

be followed by construction side during assemblies erection

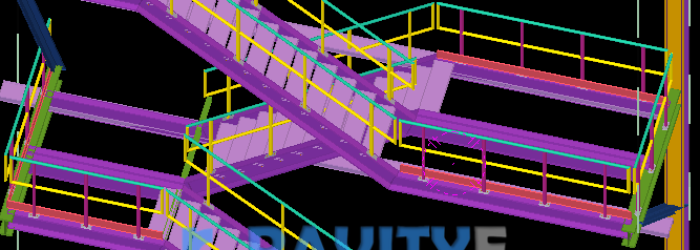

Miscellaneous Steel Detailing

We are using the best 3D BIM modeling software for detailing such as Tekla, SDS2 etc. We make sure you get the professional craftsmanship you need to get the job done. Drawings, models, required electronic files and reports we are transferring to clients using high speed online transfer. We detail structural as well as miscellaneous steel covering industrial structures, commercial buildings and residential

Our Miscellaneous Detailing Services includes

- Staircases for Circular, Spiral, Straight etc

- Ladders like Step, Straight, Cage, Platform Ladders etx

- Hand Rails, Wall Rails etc

- Oil Tanks,Storage Tanks etc

- Pipes for Water, OIl etc

- Staircases for Circular, Spiral, Straight etc

- Ladders like Step, Straight, Cage, Platform Ladders etx

- Hand Rails, Wall Rails etc

- Oil Tanks,Storage Tanks etc

- Pipes for Water, OIl etc

PEB / PEMB Steel Detailing

When it comes to Pre-Engineered Metal Building designs, there's no one better to turn to than Gravity Steel. With years of experience under our belts, our team of experts has successfully completed over 50+ projects, ranging from factories to schools. You can trust us to provide accurate and reliable designs at highly competitive prices. We use only the latest technology and software, such as Tekla and SDS/2, and work with global standards such as AISC, CISC, IS, BS, and Euro.

At Gravity Steel, we take pride in our work culture, which is based on transparency and ethics. We believe that our customers are our top priority, which is why we provide dedicated project managers and exclusive account managers to every one of our clients. We understand that every project is unique, which is why we give you the flexibility to customize your project to meet your specific needs and requirements.

When you choose Gravity Steel for your Pre-Engineered Metal Building designs, you're choosing a team of experts who are committed to delivering top-quality results every time. So why wait? Contact us today to see how we can help you with your next project!

The following below types of projects we undertake

- Ware House & Storage Sheds

- Manufacturing Plants & Factories

- Schools & Universities

- Hospitals & Clinics

- Churches & Prayer Halls

- Gas Stations

- Airport Hangers

- Railways & Metros Station Buildings

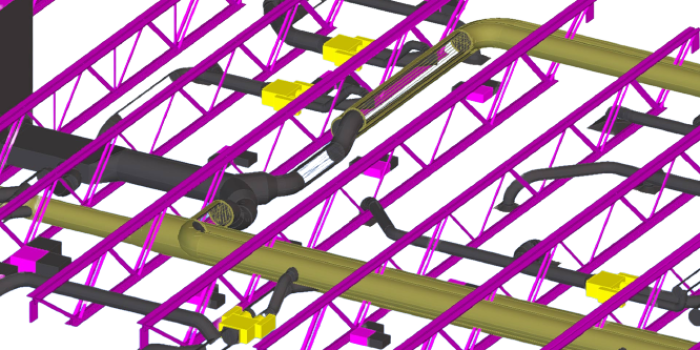

Steel Joist & Joist Girder Detailing

Detailing joists and joist girders is very specialized. We use the SJI code for all the joist related detailing for the joist fabrication and erection processes. We take a responsibility in coordination between structural details and joist details as well to make sure there will be no errors while execution of the project. We'll provide the drawings for joist placement plans and coordination requirements and help promote harmony between structural and joist erection drawings. We'll also review best practices for the flow of information and coordination.

Our top-notch services involve preparing complete and accurate lists and bills for Nucor- Vulcraft, Canam, and New Millennium products specified in the Structural Design Drawings.

Our Joist detailing service include the below deliverables

- 3D Modelling

- Connections to Steel & Joist

- Connection Bolt Plans

- Erection / General Arrangement Drawings

- Fabrication / Shop Drawings

- Single Part / Gather Drawings

- Material Takeoff / Advance Bill of Material

- Reports of Joist List, Part List, Bolt List

- IFC File / Web Viewer

- NC, DXF, Kiss Files

- Coordination drawings for Steel

- Customized Reports as per client requirement

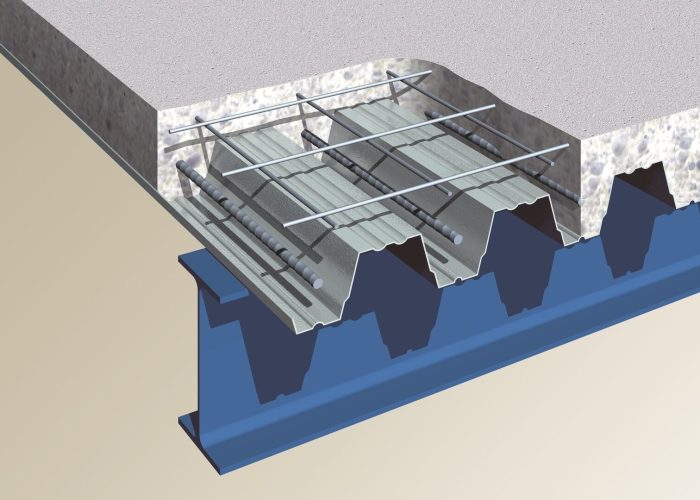

Deck Detailing

Gravitye Steel Structures is a reliable and committed team that specializes in providing Deck Detailing services for Structural Steel Projects and Pre-Engineered Metal Buildings. Our company is proud to strictly adhere to global standards such as AISC, NISD, BIS, CISC, OSHA, and ASTM, which has enabled us to build an outstanding reputation and expand our client base. Our team primarily works on SDS/2 and TEKLA platforms, which are supported by top-of-the-line state-of-the-art technology.

We also draft erection plans, elevations, sections, and details for the appropriate and safe installation of the joist and deck. We typically coordinate these services with the structural steel detailing as an effective option for time-sensitive projects.

Our Joist detailing service include the below deliverables

- 3D Modelling

- Connections to Deck, Steel & Joist

- Erection / General Arrangement Drawings

- Fabrication / Shop Drawings

- Material Takeoff / Advance Bill of Material

- Reports of Joist List, Part List, Bolt List

- NC, DXF, Kiss Files

- Coordination drawings for Steel

BIM Services

Welcome to Gravity Steel Structures, A Prominent BIM Service Provider with a strong global foothold. We have a team of Architects and Engineers with excellent BIM project execution capabilities for USA, UK, Australia, Canada and European buildings. Delivering quality BIM Models have always been our ultimate focus.

We work with latest technical infrastructure, diverse software. We have well-defined BIM work flows and Quality check lists to ensure that the projects are delivered with utmost precision. We believe in providing our clients value for money Clash Detection, 3D BIM Coordination and Coordinated Shop Drawings are one of our key services. We facilitate BIM coordination meetings with client online and ensure that the modifications and design changes are communicated efficiently and there are no missing links. Architects, Stakeholders, Engineers and end client are all a part of this meeting. We use Navisworks for clash detection services and extract clash reports to facilitate Coordination. Our cost-effective, timely and qualitative deliverables coupled with a penchant to provide client centric service that has made us one of the top BIM Service Providers in India.

Our BIM Services we offer for below projects,

- Residential Projects

- Commercial Projects

- Schools & Residential

- Public Buildings

- Highways & Bridges

- Hotels & Resorts

- Health Care & Hospitals

- Heritage Buildings